Construction Industrial Crimping Tool in Rockford

Industrial crimping tools are industrial strength pliers that are used to create industrial-grade joints. Industrial crimping tools are typically made of metal or plastic and can be found in many different sizes depending on the type of industrial joint they will be making. If you want to get into industrial construction, then it’s important to know how industrial crimping tools work! Read more about industrial crimping tools here.

How to choose the right crimping tool for your needs

When choosing an industrial crimping tool in Rockford, it is important to be aware of what types are available. There are three basic styles of industrial crimping tools: the jet style – ring or tongue and groove, the press style which is used for more heavy-duty jobs. Another crimping tool is the ratcheting type – adjustable jaws allow the user to make repeated connections without readjusting the tool in between each connection. This can save time when making multiple connections during a job or project!

Industrial crimping tools will have one of three types of industrial joints that they can make:

Butt splice industrial joint

This type is an insulated wire or cable connector used to join two conductors together. In addition, it has a heat shrink tube that protects the connection from dirt and moisture while adding color coding for easy identification.

Wire end industrial joint

This is used when terminating wires with solderless ends such as insulation displacement connectors (IDC) or similar devices. This industrial crimping tool also helps protect against water infiltration into the termination point by surrounding IDCs in a rubber boot cover where the wire enters onto the terminal base plate.

Forked lug industrial joint

These are metal tubes that fit over a stripped wire end and are held in place with a screw. The industrial crimping tool in Rockford is used to connect the lug onto a connector or splice where there is no insulation available that can be removed from the cable, such as when terminating bare conductors into junction boxes.

Forked industrial wire stripping

This industrial crimping tool has an adjustable blade depth guide for ease of operation when removing jacketing from stranded cables while maintaining a proper conductor strand twist ratio during the termination process. It also features a self-sharpening knife blade which needs less maintenance than standard industrial crimping tools on market today.

Advantage of using a professional-grade industrial crimping tool in Rockford

It is important to select a professional-grade industrial wire stripping and termination tool that has been designed for use with copper conductors. The Forked industrial wire stripping – this industrial crimping tool features an adjustable blade depth guide, which makes it easier than ever before to remove insulation from stranded cables while maintaining proper conductor strand twist ratio during the termination process. It also boasts a self-sharpening knife blade so you don’t have to worry about maintenance as much as other tools on market today.

Made in the

— USA —

All Kebby products are proudly manufactured

and assembled in our Rockford, IL facility

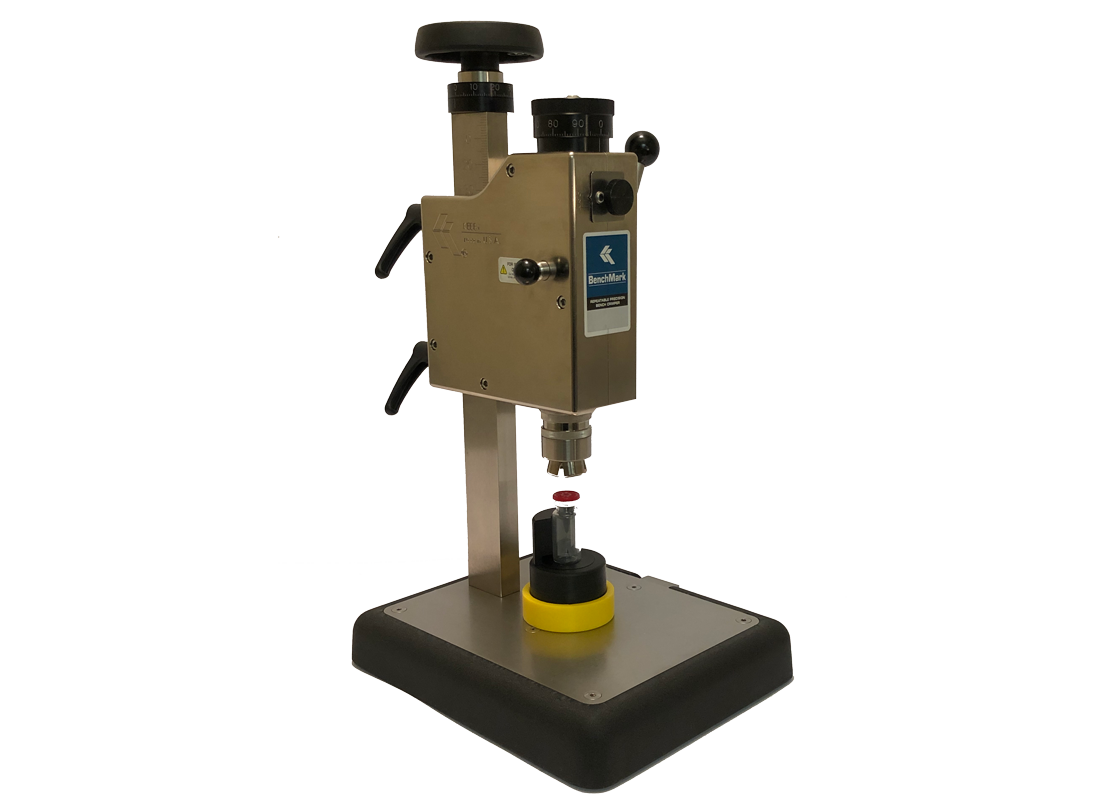

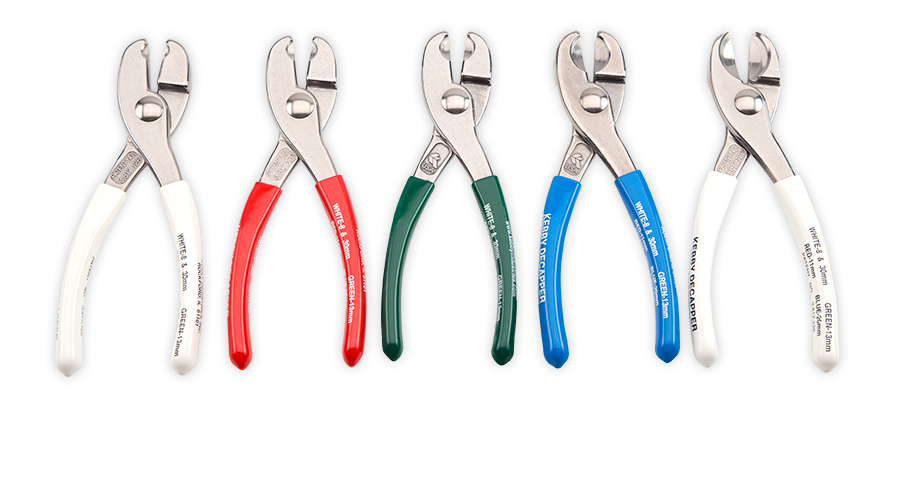

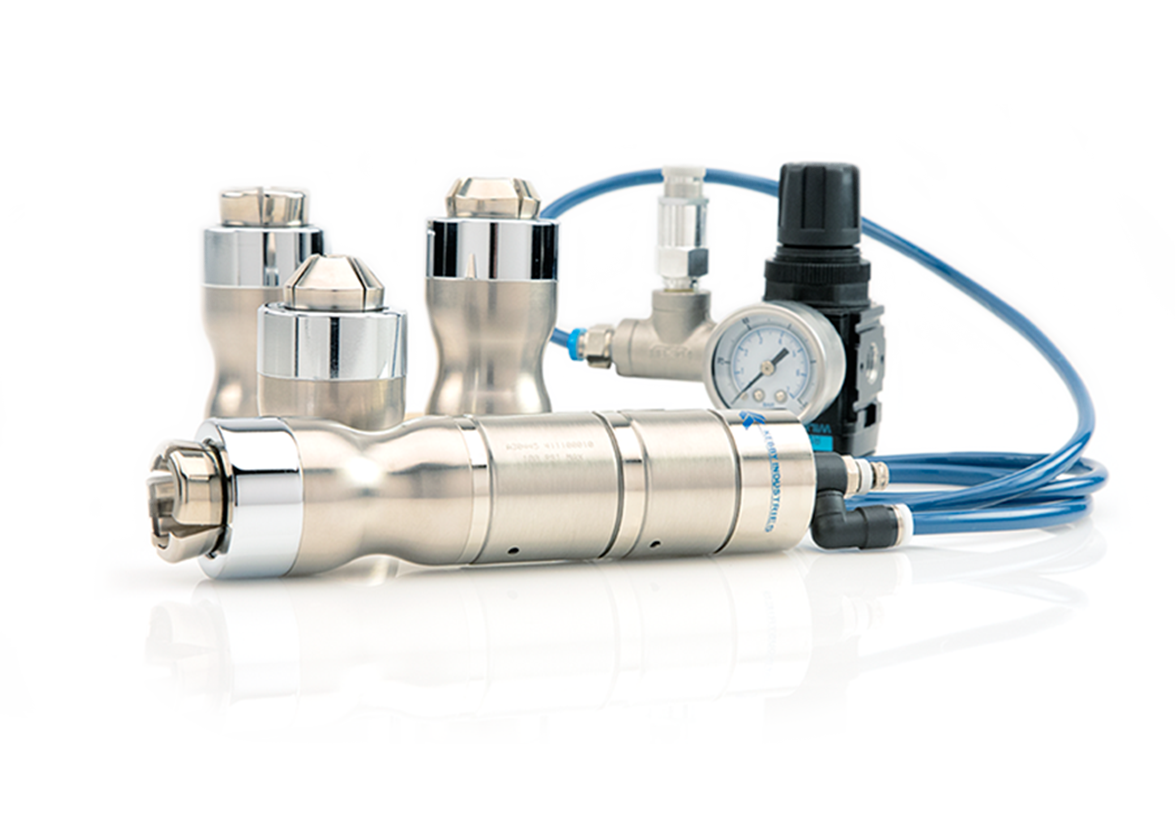

Vial Crimper and Decapper Hand Tools and Equipment

Kebby Industries, Inc. manufactures and provides vial crimper and decapper products for crimping and decapping vials and bottles with aluminum crimp seals that are used in general laboratory applications and also sample preparation for chromatography. Kebby Industries began making hand crimpers and decappers in 1973. Since then, we have expanded our product line to include pneumatic and manual benchtop units along with our hand tool products. We currently manufacture vial crimpers and decappers to work with nearly 100 different sizes and styles of vial crimp seal, and we provide our products to customers on a global level.