The Uses of Vial Crimper and Decapper

The course of action of crimping an aluminum seal onto a pre-stoppered vial shouldn’t be overlooked or underemphasized. Inside the pharmaceutical industry, there’s a have to have for a sophisticated and helpful seal not just from the cosmetic viewpoint, but also extra importantly, due to the correlation between seal top quality and container closure integrity. Even in laboratory settings and in the course of early-stage evaluations of a drug item and containment program, reliable, robust, and consistent crimped seals are needed.

Historically, challenges can arise resulting from unoptimized vial crimper and decapper processes or gear. Often the usage of jaw-type crimping devices can generate defects due to the dimensions in the jaw head not getting accepted for the vial, stopper, or seal. Also, in the event the downward stress onto the vial is not suitable or uniform, a defect can outcome in the jaws prematurely squeezing the skirt prior to getting in the desired position from the vial crown. If a jaw-type crimper has to be utilized, the recommendation should be to have a distinctive jaw-head modify part for each combination of the vial, stopper, and seal. Also, downward stress must be optimized.

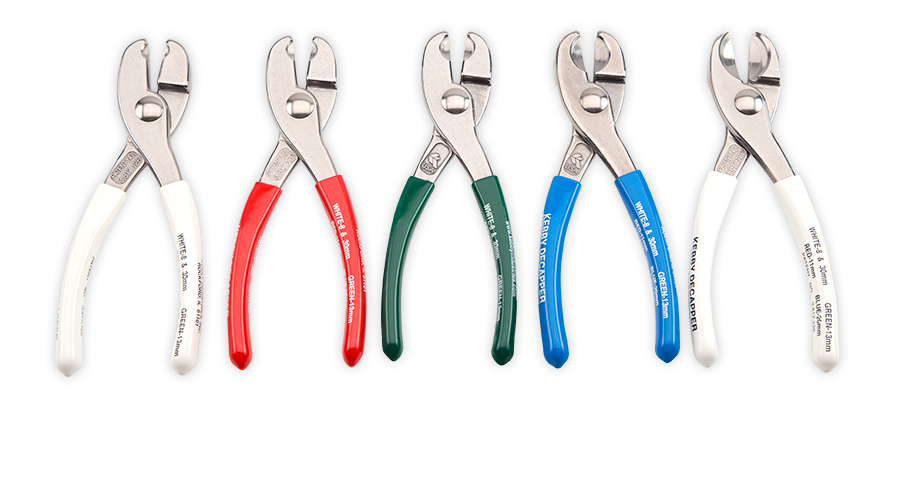

Manual Vial Crimper and Decapper Tools

The regular crimping tools are robust metal crimpers with blocky handles enabling you to grab and press them at any position. They are height adjustable by a hexagon important that could move the inner part of the head up and down. Crimping pressure is usually set by a screw in the deal and be fixated by a nut. Manual common crimpers are obtainable for crimp caps N 8, N 11, N13, and N 20 too as for Flip Top / Flip Off caps N 13 and N 20.

Electronic crimping tools

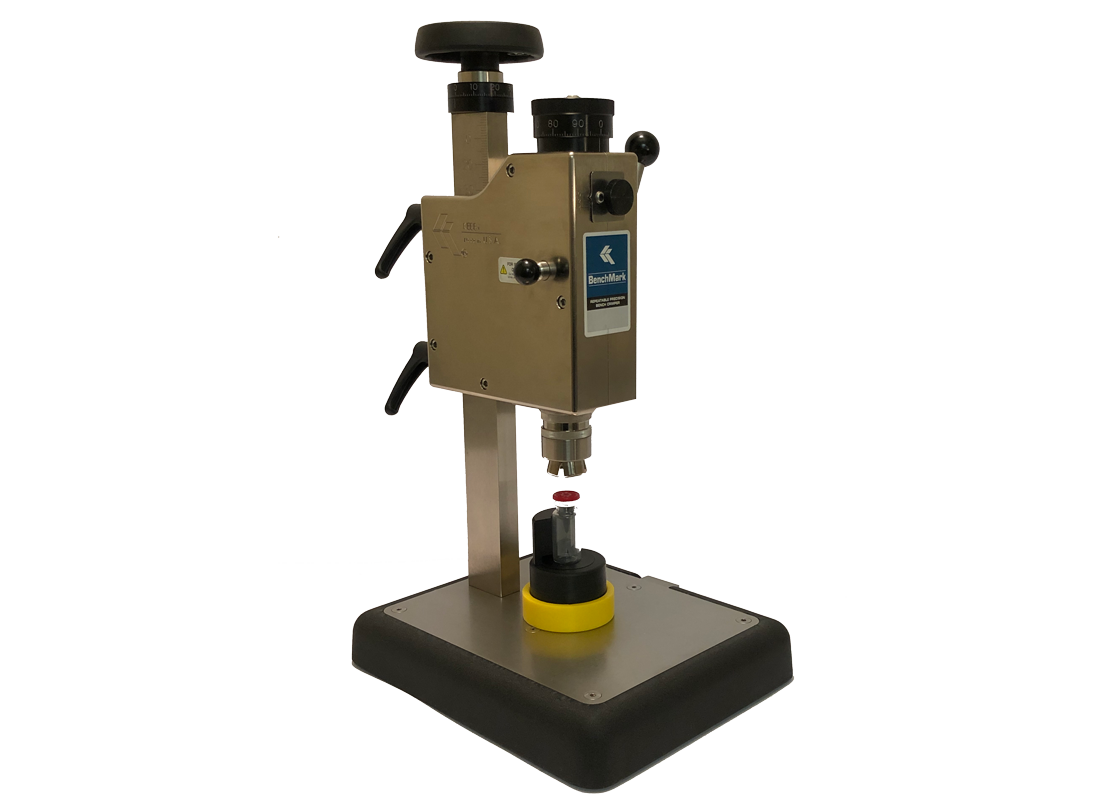

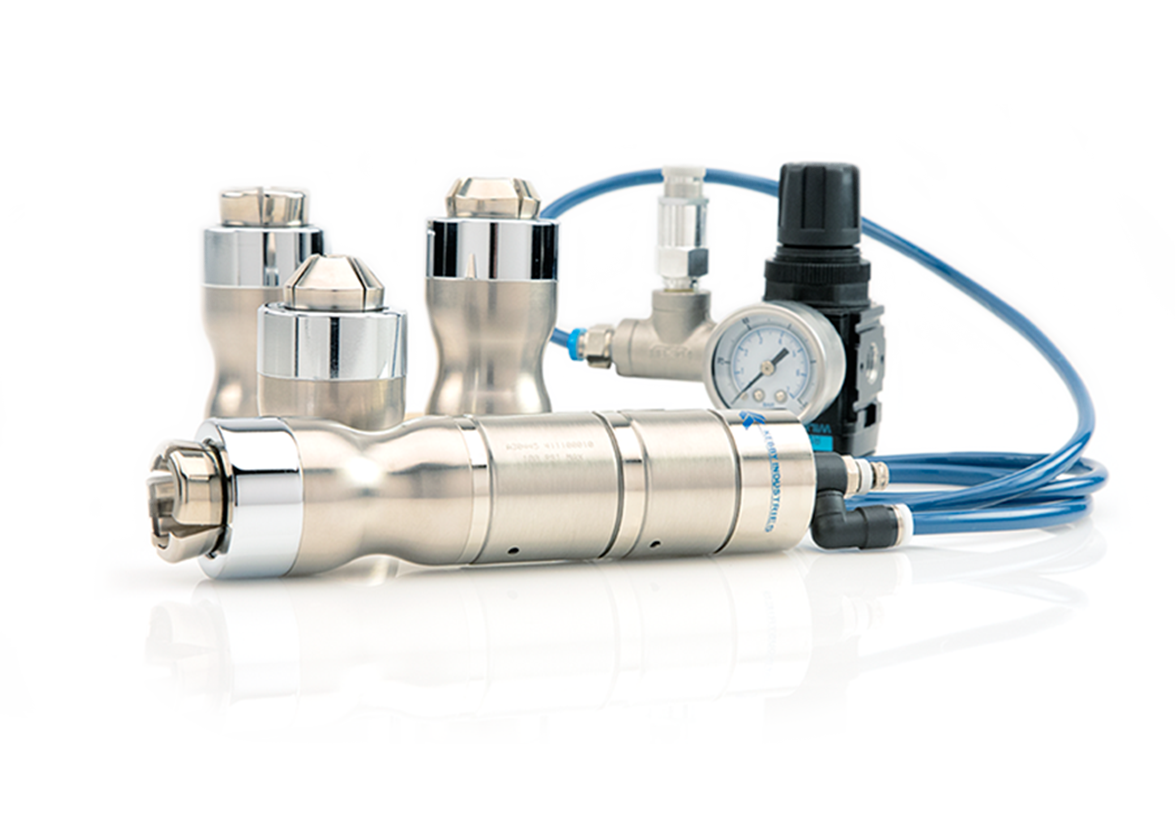

Prospects with larger sample throughput can select involving either battery-powered electronic crimping tools or maybe a stationary Higher Power crimping tool with fixed power supply and exchangeable crimping/decapping heads. All electronic crimping tools possess a brushless motor (extended lifetime), an OLED show, and no serviceable components. They may be delivered with a CE certificate and have a 1-year warranty.

Battery-powered electronic crimping tools

These mobile tools offer a higher consistency and reproducibility of crimp final results than manual tools. Their crimping stress is adjustable by the managing unit on prime from the tool (OLED show). They may be powered by extended-lasting lithium-ion cell batteries (complete battery charge for a number of hundred vials, lifetime of battery > 1500 charges). Throughout charging (approx. 1-2 hours) the tool nonetheless might be used. Except for the replacement battery 735500, you will discover no serviceable parts. Numerous plug clips for charging in nearly all countries come in conjunction with the tool and language choice in the OLED show supports international usage. For crimping and decapping 1 tool each and everyone is needed.

Adjusting Vial Crimper And Decapper For Use

The vial crimper and decapper have to be adjusted for the vials, caps, and seals which will be applied. The adjustment knob on the major with the tool is usually turned to set the quit position for the stroke from the tool. The adjustment with the crimping tool is properly a height adjustment. The setting determines the level of compression in the cap and is quite precise. There may be some drifting over time as a result of stretching or wearing-in of components of the new crimper, but frequently the reproducibility from the crimp is as very good as the consistency from the vials and seals.

Made in the

— USA —

All Kebby products are proudly manufactured

and assembled in our Rockford, IL facility

Vial Crimper and Decapper Hand Tools and Equipment

Kebby Industries, Inc. manufactures and provides vial crimper and decapper products for crimping and decapping vials and bottles with aluminum crimp seals that are used in general laboratory applications and also sample preparation for chromatography. Kebby Industries began making hand crimpers and decappers in 1973. Since then, we have expanded our product line to include pneumatic and manual benchtop units along with our hand tool products. We currently manufacture vial crimpers and decappers to work with nearly 100 different sizes and styles of vial crimp seal, and we provide our products to customers on a global level.